Sep 27,2023

Take you to learn about hydraulic cylinders

Introduction to hydraulic cylinder manufacturers: Regarding the selection of hydraulic cylinder models, the main factors are the inner diameter and operating pressure of the hydraulic cylinder. For example, if the stroke is 300MM and the thrust is 4000KG, and the thrust is 4T, it can be calculated that if the working pressure of the oil cylinder is designed to be 8MPA, the inner diameter of the oil cylinder is 80, and the oil cylinder model is 80 * 40 * 300-8MPA. A rod oil cylinder can be used for easy maintenance. If the working pressure of the oil cylinder is 16MPA, the inner diameter of the oil cylinder is 60, and the oil cylinder model is 60 * 35 * 300-16MPA, which can be welded, connected or pulled. It is recommended to determine the operating pressure of the oil cylinder based on the system pressure of the mechanical equipment.

Sep 27,2023

How to reduce the degree of damage to hydraulic cylinders?

The damaged parts of hydraulic cylinders are mostly located in the curved area connecting the flange and the cylinder wall, followed by the curved area transitioning from the cylinder wall to the cylinder bottom. There are a few cracks on the cylinder wall, some of which are damaged due to severe cavitation. In terms of usage conditions, fatigue damage generally occurs when a higher number of operating loads are experienced during damage, and cracks gradually form and propagate. There are many factors that affect the service life of hydraulic cylinders, and analysis should be conducted based on specific situations. However, generally speaking, there are several aspects:

Sep 27,2023

Do you know how to exhaust engineering hydraulic cylinders?

Under normal circumstances, the exhaust equipment for hydraulic cylinders in construction machinery should be located at the top of the hydraulic circuit, so it is not necessary to install it on the engineering hydraulic cylinder. However, when selecting the engineering hydraulic cylinder, we need to clearly indicate whether the exhaust equipment is needed or in which direction it should be located.

Sep 27,2023

Where are the application areas of industrial hydraulic cylinders?

Industrial hydraulic cylinders utilize the pressure of liquids for operation, and control the movement of mechanical equipment through internal components such as pistons and seals. Mainly composed of cylinder body, piston, seals, sealing rings, hydraulic connection ports, etc. The basic principle is to use hydraulic cylinders to receive high-pressure fluid flow, causing the piston to produce a certain displacement after being subjected to force, thereby driving the movement of relevant mechanical parts.

Sep 20,2023

Abnormal operation of hydraulic cylinder components

During the operation of hydraulic cylinders, the lack or damage of individual components often affects the use and construction period of the entire mechanical equipment. Therefore, users should be able to flexibly handle some seemingly difficult problems in the use and maintenance of hydraulic cylinders.

Sep 20,2023

According to the different technical requirements of hydraulic cylinders, seals must also be produced according to the technical requirements of the cylinders. Mr. Li mainly analyzes the oil cylinder seals for the following two types of pressures.

Sep 20,2023

Hydraulic cylinder, abbreviated as hydraulic cylinder, is an important executive component in the hydraulic system, playing a role as an executive component in the entire hydraulic machinery. Its function is to convert hydraulic energy into linear, oscillating reciprocating mechanical motion. Throughout the process, hydraulic cylinder converts hydraulic energy into mechanical energy, mainly in the fields of automobiles, energy equipment, petroleum, ships, etc. downstream.

Sep 04,2023

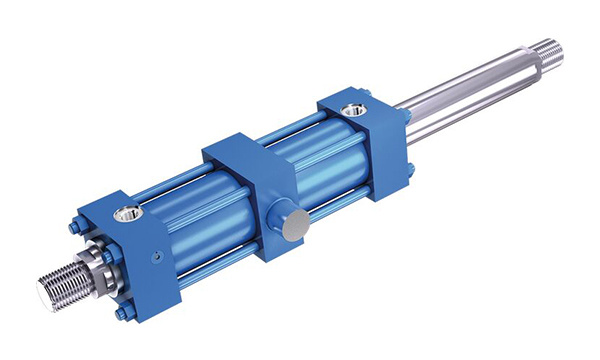

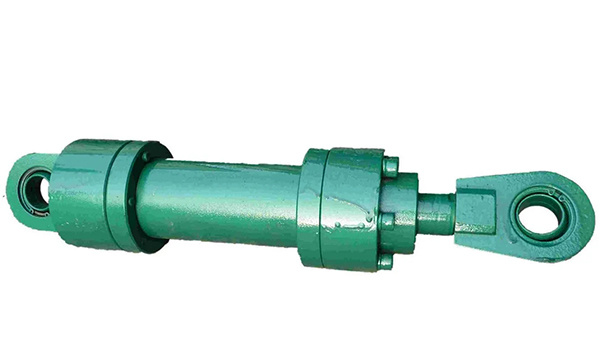

Introduction to the structure and types of hydraulic cylinders

Hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or swing motion). It has a simple structure and reliable operation. When using it to achieve reciprocating motion, there is no need for a deceleration device, and there is no transmission clearance, making the motion smooth. Therefore, it is widely used in various mechanical hydraulic systems. The output force of the hydraulic cylinder is directly proportional to the effective area of the piston and its pressure difference on both sides; Hydraulic cylinders are basically composed of cylinder barrels and cylinder heads, pistons and piston rods, sealing devices, buffer devices, and exhaust devices. The buffer device and exhaust device depend on the specific application scenario, while other devices are essential.

Sep 04,2023

How to quickly diagnose faults in hydraulic cylinders

Hydraulic cylinder is an actuator that converts hydraulic energy into mechanical energy in a hydraulic system. Its faults can be basically summarized as hydraulic cylinder misoperation, inability to push load, and piston sliding or crawling. It is not uncommon for equipment to shut down due to hydraulic cylinder malfunctions. Therefore, attention should be paid to the diagnosis and maintenance of hydraulic cylinder malfunctions.

Sep 04,2023

Introduction to hydraulic cylinders

Hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or swing motion). It has a simple structure and reliable operation. When using it to achieve reciprocating motion, there is no need for a deceleration device, and there is no transmission clearance, making the motion smooth. Therefore, it is widely used in various mechanical hydraulic systems.

Related Posts

Contact Us

Address:No. 88, Gaoqing Road, Qingshanhu Street, Lin'an District, Hangzhou City, Zhejiang Province, China

Postal Code:311305

Phone:+86-0571-87938113,87938137

E-mail:hc208@zjimee.com.cn