Where are the application areas of industrial hydraulic cylinders?

Sep 27,2023

1、 The basic principle and structure of industrial hydraulic cylinders

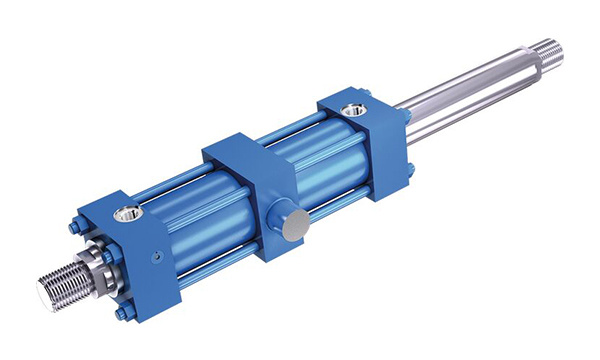

Industrial hydraulic cylinders utilize the pressure of liquids for operation, and control the movement of mechanical equipment through internal components such as pistons and seals. Mainly composed of cylinder body, piston, seals, sealing rings, hydraulic connection ports, etc. The basic principle is to use hydraulic cylinders to receive high-pressure fluid flow, causing the piston to produce a certain displacement after being subjected to force, thereby driving the movement of relevant mechanical parts.

2、 Application fields of industrial hydraulic cylinders

1. Metallurgical industry: Industrial hydraulic cylinders play a crucial role in the metallurgical industry, specifically applied in fields such as steelmaking equipment, casting machinery, rolling mills, continuous casting machines, and lifting machinery. Its powerful driving force and stable performance help the metallurgical industry improve production efficiency and quality.

2. Heavy industry: Industrial hydraulic cylinders are also widely used in heavy industry, such as construction machinery, excavators, loaders, forklifts, etc. The application of hydraulic cylinders is indispensable in various hydraulic systems of these equipment. Its reliability and load-bearing capacity can meet the requirements of heavy-duty machinery for power transmission and working loads.

3. Mechanical manufacturing: In the mechanical manufacturing industry, industrial hydraulic cylinders are also widely used. For example, CNC machine tools, printing machinery, packaging machinery, and injection molding machinery. The high-speed movement and precise control of industrial hydraulic cylinders can improve the accuracy and production efficiency of mechanical equipment.

3、 The development trend of industrial hydraulic cylinders

1. Intelligence: With the advancement of Industry 4.0, industrial hydraulic cylinders are also developing towards intelligence. Through the application of sensors and control systems, functions such as status monitoring, remote control, and fault diagnosis of hydraulic cylinders can be achieved, improving the reliability of equipment operation and the convenience of maintenance.

2. Energy conservation and environmental protection: The improvement of environmental protection awareness has made the energy-saving and environmental protection characteristics of industrial hydraulic cylinders an important direction for development. Adopting high-efficiency power devices and optimized fluid systems, reducing energy consumption and oil leakage, improving system efficiency and the service life of industrial hydraulic cylinders.

3. Lightweight: Industrial hydraulic cylinders are also developing towards lightweight while ensuring strength and load-bearing capacity. By adopting new materials, structural design, and manufacturing technology, the volume and weight of oil cylinders are reduced, and the movement speed and flexibility of mechanical equipment are improved.

Industrial hydraulic cylinders, as an important technical equipment, are widely used in various fields to help mechanical equipment achieve efficient motion control. In the future, industrial hydraulic cylinders will continue to develop towards intelligence, energy conservation, environmental protection, and lightweight, providing more reliable and efficient technical support for industrial automation.

Related Posts

Contact Us

Address:No. 88, Gaoqing Road, Qingshanhu Street, Lin'an District, Hangzhou City, Zhejiang Province, China

Postal Code:311305

Phone:+86-0571-87938113,87938137

E-mail:hc208@zjimee.com.cn